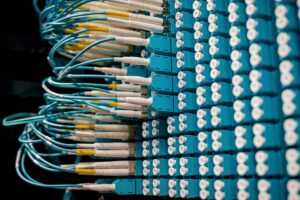

Improve Wire & Cable Compounds with Quality Polymers

Conventus knows wire and cable manufacturers only want the best material for their components. High and low voltage cables and wires require high-quality insulation made of specific polymers that are flame retardant as well as resistant to extreme temperatures, tears, and abrasions. These polymers must also be able to maintain ductility and flexibility so the wires and cables can bend and move without breaking.

Polymers and elastomers used for wire & cable applications can include:

- Ethylene Propylene Diene Rubber (EPDM)

- Ethylene Vinyl Acetate (EVA)

- Nylon 6 (PA6)

- Polyetheretherketone (PEEK)

- Polyethylene (LDPE, LLDPE, HDPE)

- Polyolefin Elastomers (POE)

- Polyphenylsulfone (PPSU)

- SILTEM™ Polyetherimide (Si-PEI)

- Thermoplastic Polyurethane (TPU)

- Thermoplastic Vulcanisate (TPV)

When you need high-performance polymers for your wire and cable compounds, we have exactly what you need. Our team of resin experts can help you find precisely what you’re looking for, working alongside you to find the best solutions for your wire & cable applications.

Need high-performance polymers for your wire & cable compounds?

Contact Conventus today to learn more.